Introducing CNC Predictive Maintenance MindSphere App

This week, we released our first app on the MindSphere Store. MindSphere is the open cloud-based IoT operating system from Siemens. The CNC Performance Improvement and Predictive Maintenance app allows more accurate planning of machine maintenance. Originally developed for a specific customer, the app is now available for customization and commissioning for any facility wishing to reduce CNC maintenance costs.

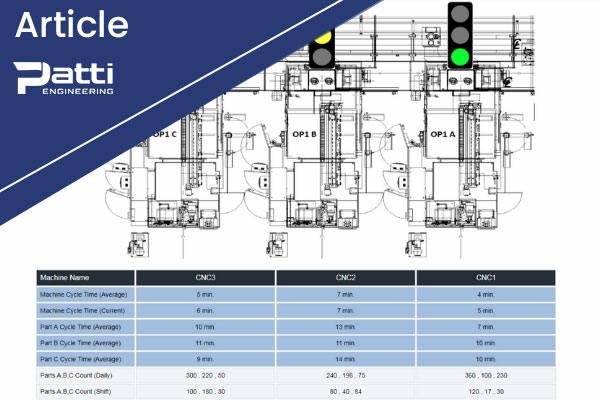

This web-based application collects and analyzes real-time data from any CNC machine to develop process improvements. This can help increase machine availability and reduce maintenance costs. As a result, product quality is consistent, and maintenance is proactive. With the help of CNC PIPM, plant managers can optimize to increase throughput and tool life while decreasing unplanned downtime. CNC PIPM is configured for each CNC machine in such a way to establish connectivity between the CNC controller in one end and MindSphere in another end. It uses MindSphere capacity to run on the cloud. Thanks to MindSphere platform openness, CNC PIPM can establish the connection with any CNC machines regardless of communication protocols.

Features:

- Performance data and recommendations based on CNC and related machine data.

- Integrated reporting provides a holistic view of production conditions and results.

- Integration with cloud platforms, CNC related machine data.

Benefits:

- Visualize and track core data from your CNC machining processes.

- Improve the accuracy of maintenance schedules, staffing, and parts.

- Give your staff actionable steps to improve CNC processes.

- Reduce costs, improve production throughput and drive better first-time results from CNC operations.