Profibus Debugging

A customer was having a problem with their Profibus communication. The Profibus nodes were dropping out occasionally. This caused their ovens to stop working and required a system reset. This was happening a few times per month. The problem was mostly an annoyance, but if it happened when the ovens were quite hot, the quick cool down could cause their product to warp.

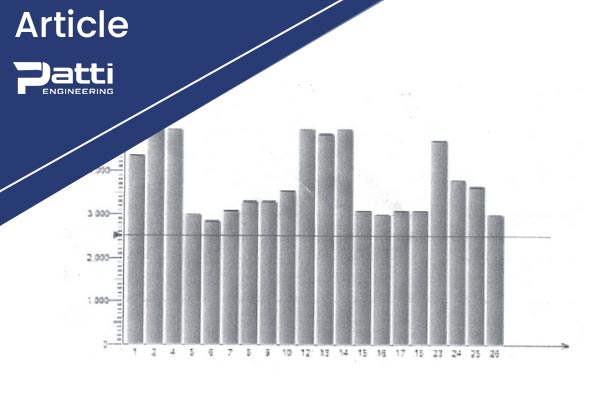

The maintenance manager at the facility had tried replacing the module to no avail. They also tried installing a signal repeater – no luck. A signal analyzer was showing that the nodes that were dropping out should have been reading around 5 volts, but instead they were reading closer to 3 volts (see “Before” charts).

One day, one of our engineers happened to be on a phone call where he mentioned the problem. John quickly calculated that the only thing that would cause that to happen was resistance in the line. And the only thing that should cause resistance in the line would be oxidation. Since wires are sealed up with jackets and protected in metal conduit, it didn’t make sense that the line itself would have resistance. However, the connectors could cause a problem. They used piercing connectors (or insulation displacement connectors) where a piece of metal pushes through the insulation. Oxidation on those connectors could certainly cause the resistance detected by the signal analyzer.

We scheduled time to go out to the facility during planned downtime and replace all of the connectors. Below, you can see the results. While the signal was all over the place before, now it’s consistent and strong. They have not had any issues with the signal dropping out since.

Replacing 33 connectors took about 8 hours. Therefore, if you are starting to notice this problem in your facility, it is best to schedule this maintenance before it requires unplanned downtime. Contact our engineers to discuss this or any other maintenance mystery you may be having.

Related categories: Blog Control Systems Integration