Tips and Tricks for Programming Wonderware SCADA System Software

Programming Wonderware SCADA

This blog post was originally written in 2018 and the tips and tricks were based on Wonderware technology at the time which may still be relevant for some. However, Wonderware solutions are now AVEVA solutions. If you need specific support for your older Wonderware SCADA system, we recommend you reach out to AVEVA’s Wonderware support.

If you are considering migrating to a new SCADA platform, we are happy to help walk you through the pros and cons of the available platforms to consider. Patti Engineering uses Siemens Industrial Edge, Ignition and other technology platforms to help manufacturers harness data collection to remove bottlenecks and optimize throughput, quality, and processes. Read this article to know more about how we help manufacturers utilize IIoT and SCADA software to boost manufacturing OEE.

Below is our original 2018 blog post on tips and tricks for working with Wonderware:

Wonderware is a SCADA solution that is being used by many different industries, some of which include infrastructure, oil/gas, chemical and more. The Wonderware platform can easily interface PLCs with HMIs across different platforms and has intuitive and creative graphics used in the software.

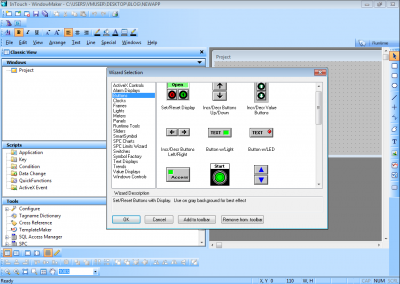

Tip 1 – Use the Wizard

Wonderware provides tools already embedded with code which makes creativity more accessible. Figure 1 presents a variety of wizards which are available in the system. These are preprogrammed buttons which only need a tag and all the other work is done.

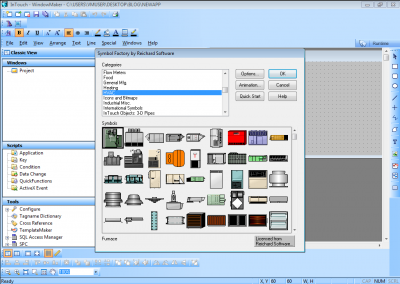

Tip 2 – Creating Symbols

Another useful tool is the “Symbol Factory,” see Figure 2. With over 60 different equipment categories and hundreds of different shapes/styles, this a unique and useful feature.

Wonderware also features many different communication protocols and user-friendly database interfacing, including SQL, DDE, and SuiteLink. Additional packages are created every few years.

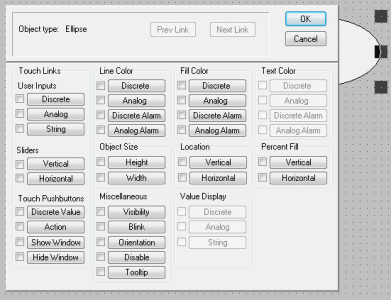

When creating symbols without using the wizard, a properties window pops up as seen in Figure 3. There are several different tabs which give you control over several different categories, for example, if I’m using a discrete fill color. I can also tie a PLC bit to the tag so that if the tag is set to zero it will be one color, and if the tag is set to one it will change to a different color. Symbols can also be changed from within the wizard, but some work is involved in doing so.

Tip 3 – Use the Query for Alarm Systems

Wonderware has its own query for alarm systems and detailed security access parameters, as seen in Figure 4. This can be very beneficial for those less experienced with programming. The alarms can also be grouped by different names, which is helpful for troubleshooting PLCs which are controlling multiple stations. Manuals give detailed explanations and examples of utilizing these features.

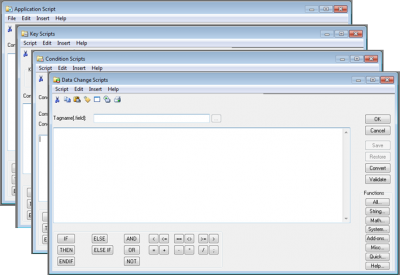

Tip 4 – Using Scripts

Key scripts are useful for associating hidden screens other users may not have access to, or quick shortcuts to screens in case an issue arises.

Overall, Wonderware is a very useful SCADA solution for industry. It is a great way to learn how to interface HMIs with PLCs and understand how data is transferred across different platforms.

Related categories: Blog Control Systems Integration