Project Summary

The FCA US LLC Indiana Transmission Plant 1 (ITP1), a customer of Patti Engineering, is relentlessly engaged in improving processes.

Challenge

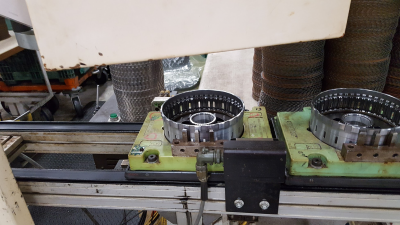

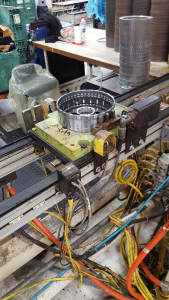

One of the processes that has been an issue for the ITP1 team is the RFID system on the sub-assembly line of the RFE rear-wheel drive transmission. This sub-assembly line consists of 10 automated stations, which are a combination of assembly and verification operations. The automation at each station is controlled by Allen Bradley SLC500 PLCs. The RFID modules identify part types, which determines the operations performed at each station. The RFID also records a pass or fail when the pallet leaves the station, directing it to either final assembly or for rework or scrap. Therefore, RFID is integral to the process.

The RFID system that FCA US was using was an old, nearly obsolete Datalogic system. These older RFID tags are battery-powered, which require the replacement of the tag batteries on a regular basis. After years of use, the tags were starting to break and the supply of available spares was getting low. Finding replacement parts was becoming extremely challenging, raising concerns about the plant’s ability to keep the line running in the future.

Even though the reliability of the current RFID system was problematic, the SLC500 control system and mechanical functionality of the line were both solid. Therefore, it made sense to try to integrate a new RFID system with the existing equipment.

Solution

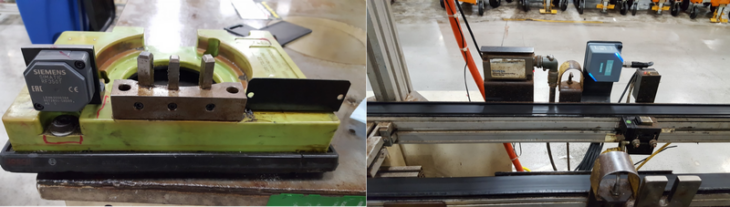

With these guidelines in mind, Patti Engineering and FCA US worked with Siemens to come up with a high frequency RFID solution using the Siemens SIMATIC RF300 series of equipment.

Hardware

The Siemens RF300 series of high frequency readers was chosen because they were developed for an industrial environment that requires consistent performance in a high-speed operation. The series coordinates with a large selection of tags for many different applications and environments, which means appropriate tags could be found for this application and would have flexibility to expand the same system if needed.

One important aspect of this project is the flexibility of the Siemens RF300 series to integrate with non-Siemens technology. In this case, the Allen Bradley SLC500 was integrated with the Siemens technology using a Profibus scanner module.

Installation

In order to keep production running, the installation and commissioning was completed over three weekends. Custom brackets were designed and fabricated to work around the existing mechanical obstructions to keep the old RFID equipment in place and functioning during the week. This allowed for a smooth, phased switchover to the new system, which resulted in zero downtime due to the installation or commissioning, and met the quota on the first production day.

Results

To date, the newly-implemented RFID system has been running seamlessly for a highly-efficient, reliable and accurate operation. Maintenance costs related to replacing batteries and parts have been eliminated. In addition, the new readers give a visual indication of the status using LED lights. For example, flashing red indicates a fault and green shows the reader is initialized. Operators can check the RFID status with just a quick glance at the machine.