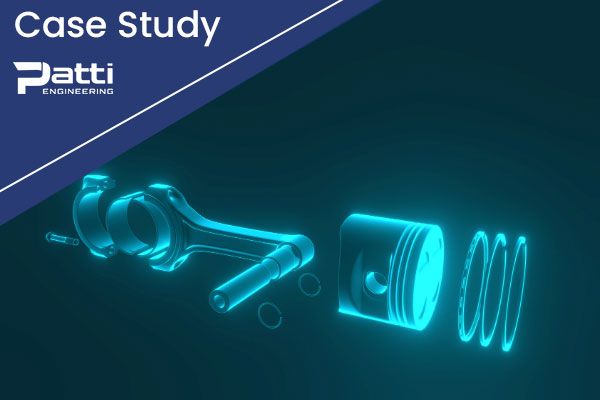

FEATURED EXPERTISE

Digital Twins

Patti Engineering's Digital Twins service provides a cutting-edge approach to optimizing industrial processes and systems. Our service creates a virtual replica of physical assets, systems, or processes, enabling clients to analyze, understand, and predict the performance of their operations with unprecedented accuracy.