FEATURED EXPERTISE

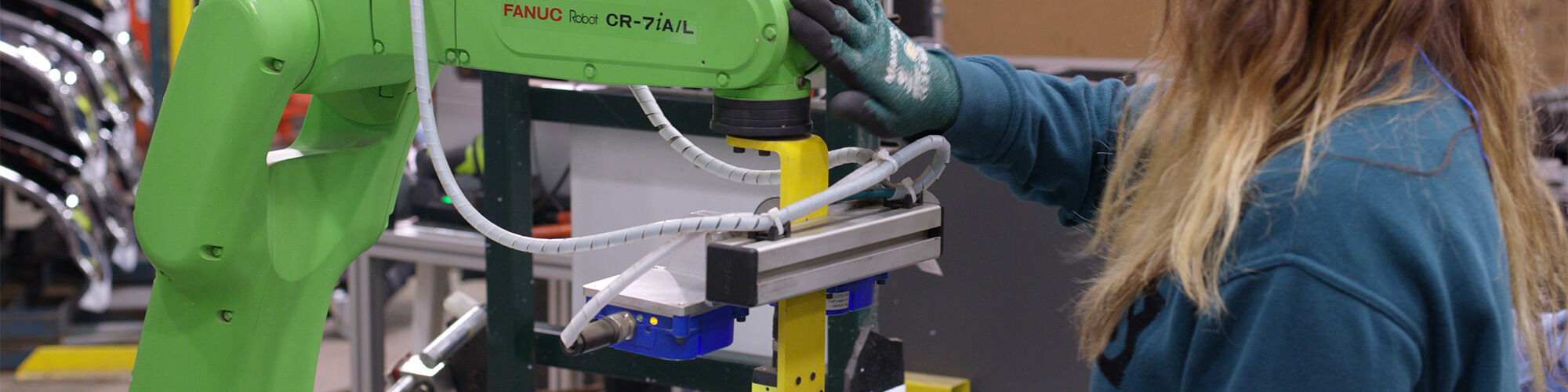

Navigating Robotics Integration in Manufacturing

Patti Engineering's Robotics Integration service merges advanced robotics with modern manufacturing requirements, embodying a synthesis of productivity enhancement and technological sophistication. Our service is specifically designed for small to mid-sized companies venturing into robotics integration, offering solutions that stretch from conceptual design to full-scale implementation.